CHALLENGER COMPOUNDER

LINHA DE GRANULAÇÃO GERAÇÃO II | GRUPO WORTEX

CHALLENGER COMPOUNDER

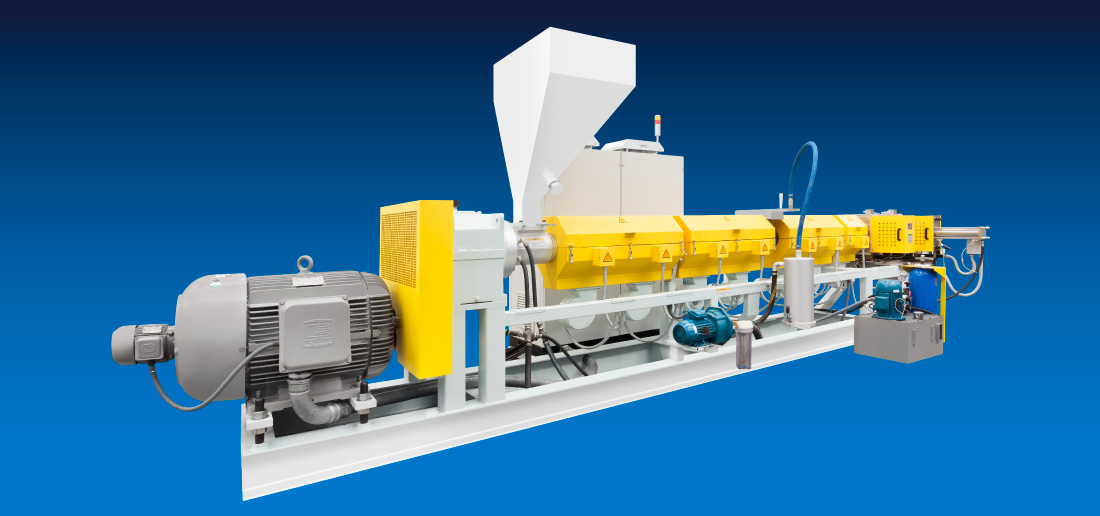

Linha Challenger Compounder, projetada para as indústrias que necessitam desenvolver e compor suas próprias blendas e reciclar plásticos rígidos. Extrusora mono rosca idealizada para substituir com qualidade e eficiência algumas máquinas de dupla rosca a um custo-benefício extremamente vantajoso. Versátil, viabiliza a reciclagem de plásticos rígidos de injeção, sopro, extrusão e aglutinados de filmes.

Linha Challenger Compounder, projetada para as indústrias que necessitam desenvolver e compor suas próprias blendas e reciclar materiais rígidos.

FINALIDADE

CHALLENGER COMPOUNDER

Linha Challenger Compounder, projetada para as indústrias que processam PP Bateria. Com duplo sistema de degasagem e dupla filtragem. Versátil, viabiliza a reciclagem de plásticos rígidos de injeção, sopro, extrusão e aglutinados de filmes.

Projetada para as indústrias que processam PP Bateria.

FINALIDADE

CHALLENGER COMPOUNDER DUO “CASCATA”

A Linha Challenger Compounder DUO “Cascata” possui duplo sistema de degasagem e dupla filtragem, permite o processamento dos materiais plásticos rígidos de injeção, sopro, extrusão e aglutinados de filmes. Extrusora mono rosca idealizada para substituir com qualidade e eficiência algumas máquinas de dupla rosca a um custo-benefício extremamente vantajoso. Versátil, viabiliza a reciclagem de plásticos rígidos de injeção, sopro, extrusão e aglutinados de filmes.

Duplo sistema de degasagem e dupla filtragem.

DIFERENCIAL

CHALLENGER COMPOUNDER ECONOLINE

A Linha Compounder Econoline é a opção projetada com menor nível de automação, visando a redução de custos, entretanto mantendo o alto nível Tecnológico de Extrusão Wortex.

Alta tecnologia aliada ao menor custo.

DIFERENCIAL

CHALLENGER COMPOUNDER CONVENCIONAL

Challenger Compounder Convencional Geração II possui corte tipo “Spaghetti” e recicla materiais rígidos de injeção, sopro, extrusão e aglutinados de filmes.

Corte na cabeça tipo “spaghetti”.

DIFERENCIAL